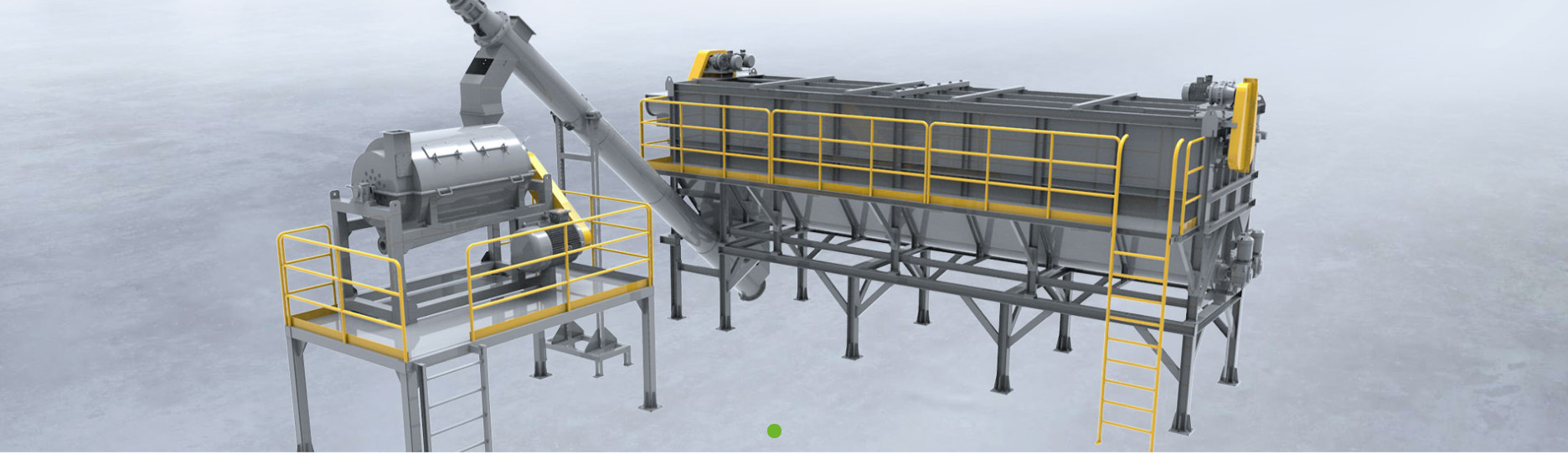

PET flakes dryer for PET recycling

The moisture content of rPET flakes is an important criterion of PET recycling. It directly affects rPET flakes as well as energy consumption during the recycling process.

The PET flakes dryer with a step-type shaft design, useful to separate water and has a cleaning function to PET flakes. PET flakes dryer separates water through centrifugal dewatering force. PET flakes are fed into the dryer through the inlet hopper, moving and forward by rotor paddles in the dryer. The last section of the shaft is a blower-like design that can transport PET to the next process. The water is thrown out through the screen, collecting in discharging hopper at the bottom of the dewatering machine and outflow.

The high speed mechanical dryer is used to remove most of the moisture on the flakes surface. PET flakes moisture rate will be reduced to 2~3% after dewatering force. To achieve lower than 1% moisture, a hot air conveying system is required to remove the moisture. It is sufficient to meet the demands of the downstream applications.

The PET flakes dryer with Special designed shaft and anti-block screens are beneficial to reach the highest output capacity and minimal moisture content. It also has the lowest breakdown rate and simpler maintenance.

Input Capacity: 1,500 – 6,000kg/h

PET Flake Dryer

PET Flake Dryer for PET recycling

PET Flake Dryer for PET recycling