Production of wood composite (WPC), industrial pallets, building materials from recycled PE plastic and rice husks

Why Use Rice Husk As Raw Material Of Composite ?

Currently in the world, natural fiber composites are widely studied using rich sources of plant fibers such as fibers, wood pulp, jute, hemp, wild pineapple, flax, rice husk… Among the natural fiber sources, however, rice husk is a natural fiber that is available every year in Vietnam in large quantities, up to over 8 million tons/year.

Under the influence of the international environment innovation, technology innovation, energy saving, environmental protection and material reuse, the use of rice husk is also increasingly interested by people.

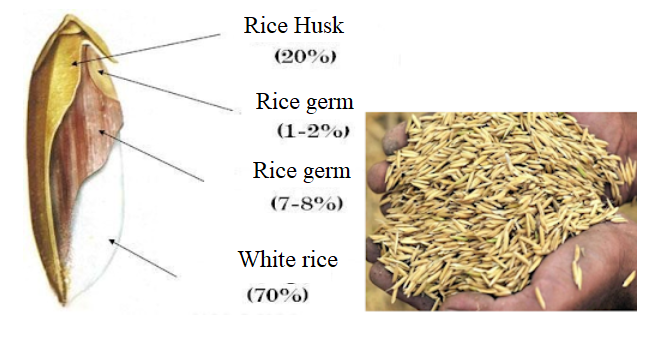

Rice husk is the most produced by-product in the rice processing process, accounting for about 20% of total rice production. Rice is also the most productive and most widely grown crop in the world. With the expansion and increase in area and production, taking advantage of that huge source of rice husk brings significant economic and social benefits.

Rice husk is hard shell outside a white rice

The traditional rice husk treatment method is using rice husk from rice processing factories as fuel, but due to the scattered rice husk processing area, the density is sparse, the stacking volume is large, the load factor is low, the quantity is therefore low. So much rice husks that rice processing plants can only dump and burn in the wilderness, this not only causes pollution but also wastes resources, therefore, people have been constantly learning about the technology to use of rice husk.

The huge amount of rice husks, if not handled, will pollute the environment and be a big waste

Therefore, the research on using rice husk as a composite material is very practical, both taking advantage of waste sources to create valuable products and solving environmental problems. The research and expansion the use of rice husks, whether from the perspective of environmental protection or resource recycling, must be based on increasing added value, preventing the release of waste (wastewater, emissions and solid waste) during production and avoid causing new pollution. In addition, the total amount of plastic waste worldwide each year is also at an alarmingly high level and can only decompose after more than 200 years of landfilling, toxic substances from waste plastic dissolve into the soil during the composting process which destroys, damages the soil and causes “white pollution”

White pollution is a burning problem today

This composite is a new material which the main raw ingredients used are rice husk and waste plastic, some lubricating auxiliary materials which is 100% industrial and agricultural solid waste. The breakthrough of rice husk composite not only improves the application field and added value of rice husk, but also reduces the problem of “white pollution” to a certain extent.

Advantages of rice husk composite materials

The composite made from rice husk and recycled PVC plastics inherit the advantages of wood and plastic.

◊ Good machining performance

This material can be sawed, shaved, lathed, cut, nailed, drilled, rubbed. Its holding force is significantly better than other composite materials.It is possible to also do second processing such as gluing and painting. In addition, it is possible to produce products with many specifications, sizes, shapes, and thicknesses, and can produce a variety of products related to color and wood grain.

◊ High hardness internal structure

Containing polyurethane which has good elasticity: Rice husk and condensed resin combination gives it good mechanical properties, such as compression and impact resistance comparable to hardwood. It is significantly better durability than ordinary wood materials, Long service life, cheap, economical, practical and excellent water resistant, corrosion resistant.

◊ Good shaping feature

The size and shape of the rice husk product shall not cause cracks, crevices, warping, deformation, and shall be free from wood nicks, slants, stains, mildew and other defects

◊ High production efficiency

This material has the characteristics of thermoplastic molding processing, short molding cycle, short processing cycle, few stages, convenient for common use

◊ Good adaptable feature

Through the chemical reaction of the auxiliary materials cause the product to occur phenomena such as agglomeration, porosity, condensation, change in properties, thereby change the density and durability of the rice husk material. It can also meet requirements for properties such as anti-aging and anti-static

◊ Looks like wood with high decorative effect

The feeling when touching is very similar to wood material: there is the warmth of wood, different from the coolness when touching plastic. High-quality rice husk composite material can also give off the aroma of rice

◊ Can be reused

Rice husk composite material can be reused and recycled. It is biodegradable, thereby protecting forest resources and ecological environment. A new type of environmentally friendly material

◊ Green environment protection

Being a new type of environmental protection composite material with good machinability, it is a good material to replace wood and steel.

The characteristics of pollution-free, acid and alkali resistance, water resistance, corrosion resistance, high strength, and it can be recycled in use.

This material is made of rice husk and thermoplastic, through high temperature, high pressure, extrusion, forming, non-toxic, odorless, can be reprocessed after use.

This is a 100% eco-friendly “green” product..

Hop International Co., Ltd specializes in providing plastics recycling solutions and manufacturing composite materials – wooded composite for building materials (WPC). Please feel free to contact us directly for detailed advice.