Bottle to Bottle PET plastic recycling

This is the highest standard of plastic recycling which is enable the recycled plastic can replace up to 100% virgin plastic in food packaging.

The key point of post-consumer PET bottle recycling is the removal percentage of impurity which is mixed in the duration from beverage factory to recycling plant. We realize the core character of different impurities based on years’ experience of practical PET bottle recycling business. The design concept of our different functional processes is to set up the best environment for separating impurities.

The recycling process includes 3 main parts: Washing, Pelleting and SSP.

1/ Washing process:

Material Description

The capacity of this recycling line is designed for baled material. If loose material were fed, the capacity will decrease accordingly.

- Minimal Bale Size : W700 x L 800 x H700 mm

- Maximum Bale Size : W1200 x L1500 x H1200 mm

- Bale Density : 150~300 kg/m3

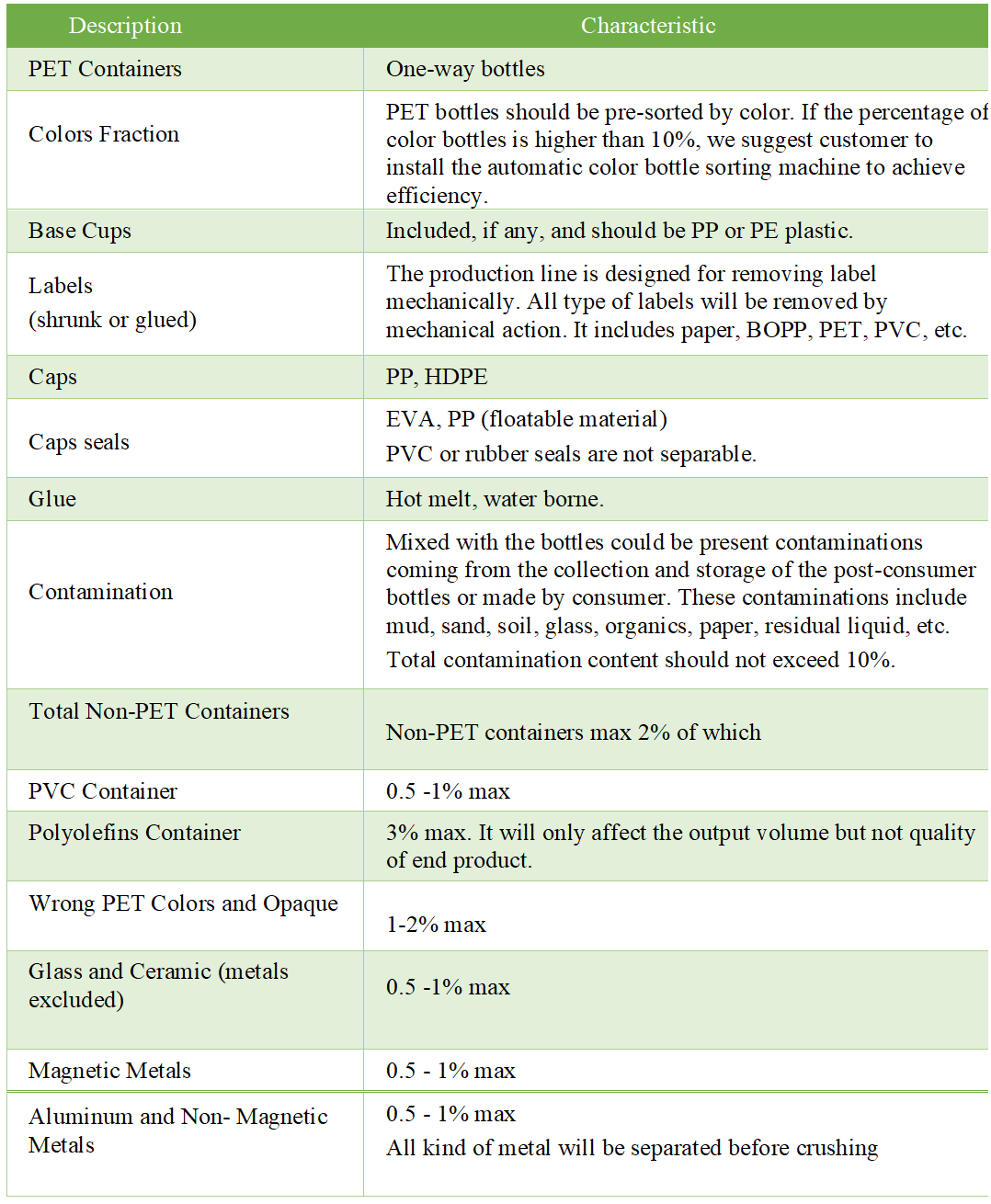

Composition of PET Bottle Bale

Input Material description for washing line

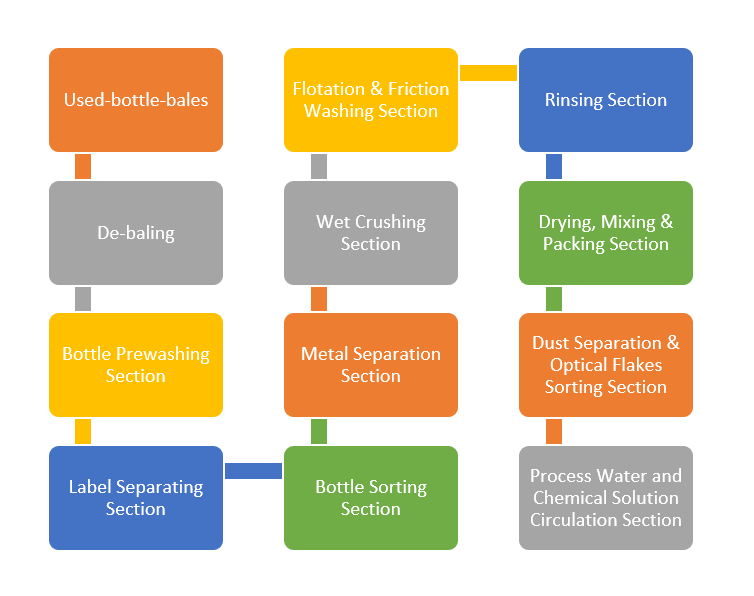

Used Bottes Recycling Washing Flowchart

PET-plastic-recycling-washing-process

Quality Criteria of Output Product (Food Grade Pellet)

It depends on the input material quality. Need to discuss before implementing the project.

2/ Pelleting & SSP Process

Input Material

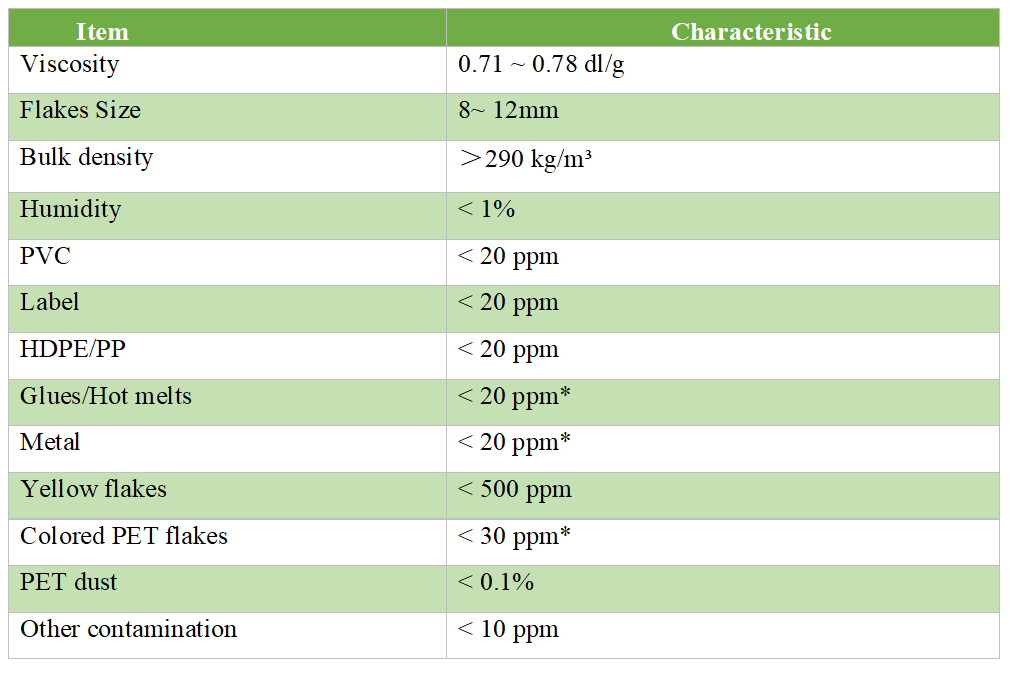

Input Flakes description

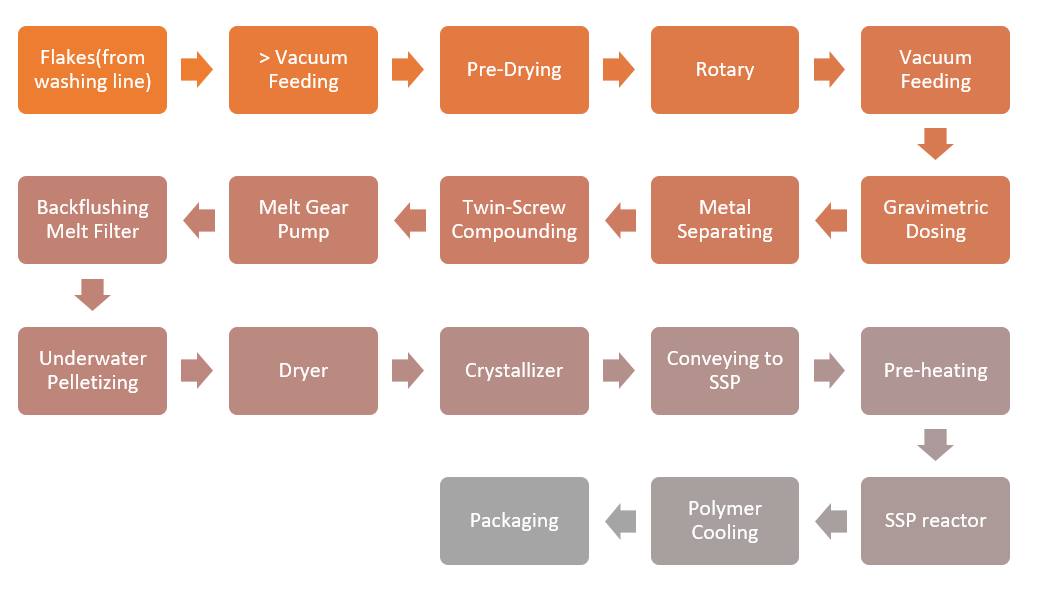

Used PET Bottle Recycling Pellting & SSP Flowchart

PET-plastic-recycling-pelleting-ssp-process

Quality Criteria of Final Product (Food Grade Pellet)

It depends on the input material quality and need to discuss before implementing the project.